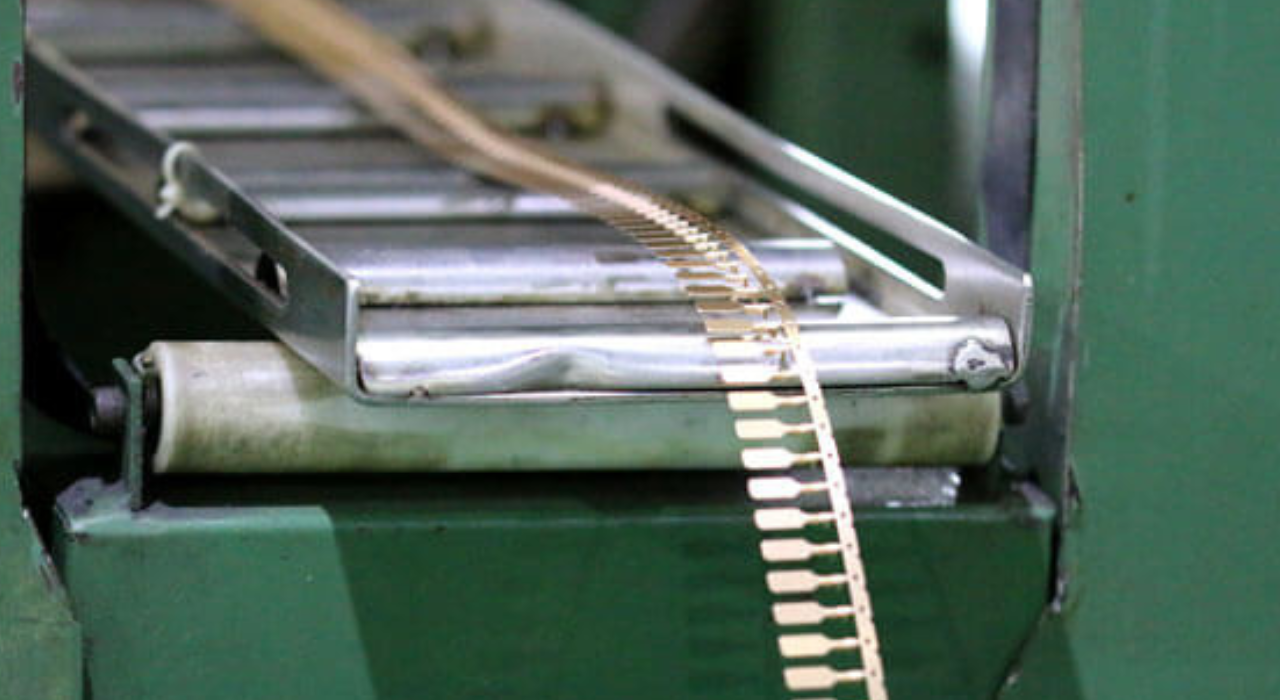

Metal stamping is super important in making things. It takes flat metal sheets and shapes them into specific forms. This handy method uses different ways to form metal, like blanking, bending, coining, and flanging. Many industries like cars, airplanes, electronics, & home appliances, use metal stamping a lot. Why? Because it’s precise and works quickly, helping to create parts that fit together perfectly.

To get what metal stamping does, you need to know how it all works. You press a metal sheet into a special mold called a die to get the shape you want. Cool technology like computer-aided design, CAD & computer-aided manufacturing, and CAM helps make the process of Metal stamping faster and more accurate. So manufacturers can whip up high-quality parts in no time.

What’s Metal Stamping?

Metal stamping is about using a press to shape or cut metal sheets. It's cost-effective & quick, especially when you need many parts made the same way. This process includes things like punching, bending, and embossing with special tools called dies. That’s why many different industries rely on metal stamping, it makes complex shapes accurately every time.

Working of Metal Stamping In Manufacturing

Now, it's important to understand the role and working principle of metal stamping in manufacturing. Basically, the metal stamping process revolves around the concept of applying pressure to a metal sheet so that its appearance can be changed to a specific shape. So how does all this happen during manufacturing? Here’s what goes down:

Designing

The first and foremost step in explaining the working of metal stamping in manufacturing is creating a die, the tool that cuts or shapes the metal. This die needs to match the part you’re making perfectly. Measuring right is super important here. Designers often use CAD software to help with those exact measurements.

Picking the Metal

Choosing the right kind of metal matters a lot in metal stamping. The material has to handle the process without breaking or losing its shape. Common choices of metal stamping include steel, aluminum, copper, and brass each with its unique traits like strength and how bendable they are. Therefore, it is suggested to go ahead with the metal that has the capabilities you need.

Setting Up the Press

Once you've got your die and selected your metal, it's time to get the stamping press ready. This machine applies force on the metal sheet and pushes it into the die so that it gets shaped correctly. There are different types of presses mechanical, hydraulic, & servo presses all with their benefits in speed & precision.

Doing the Stamping Operation

Here’s when the magic happens! The press takes turns applying pressure on the sheet over and over again. As it moves through various parts of the die, different actions happen like bending or punching to get that perfect shape we want. Sometimes it’s one stage; sometimes it’s multiple stages depending on how tricky that part is.

Checking Finished Parts

After everything's stamped out, at last, each piece gets checked for quality & accuracy! This step is super important because we want to make sure everything meets the right standards without any flaws. With advanced tools like laser scanners or coordinate measuring machines, CMM helps check if everything fits just right.

Wrapping Up

In short, metal stamping is key in manufacturing, it creates complex parts quickly while keeping everything precise! By knowing each step from designing dies to inspecting those final pieces, manufacturers can use this technique well across many fields. It not only helps with big production runs but also keeps quality high and consistent.